Introduction:

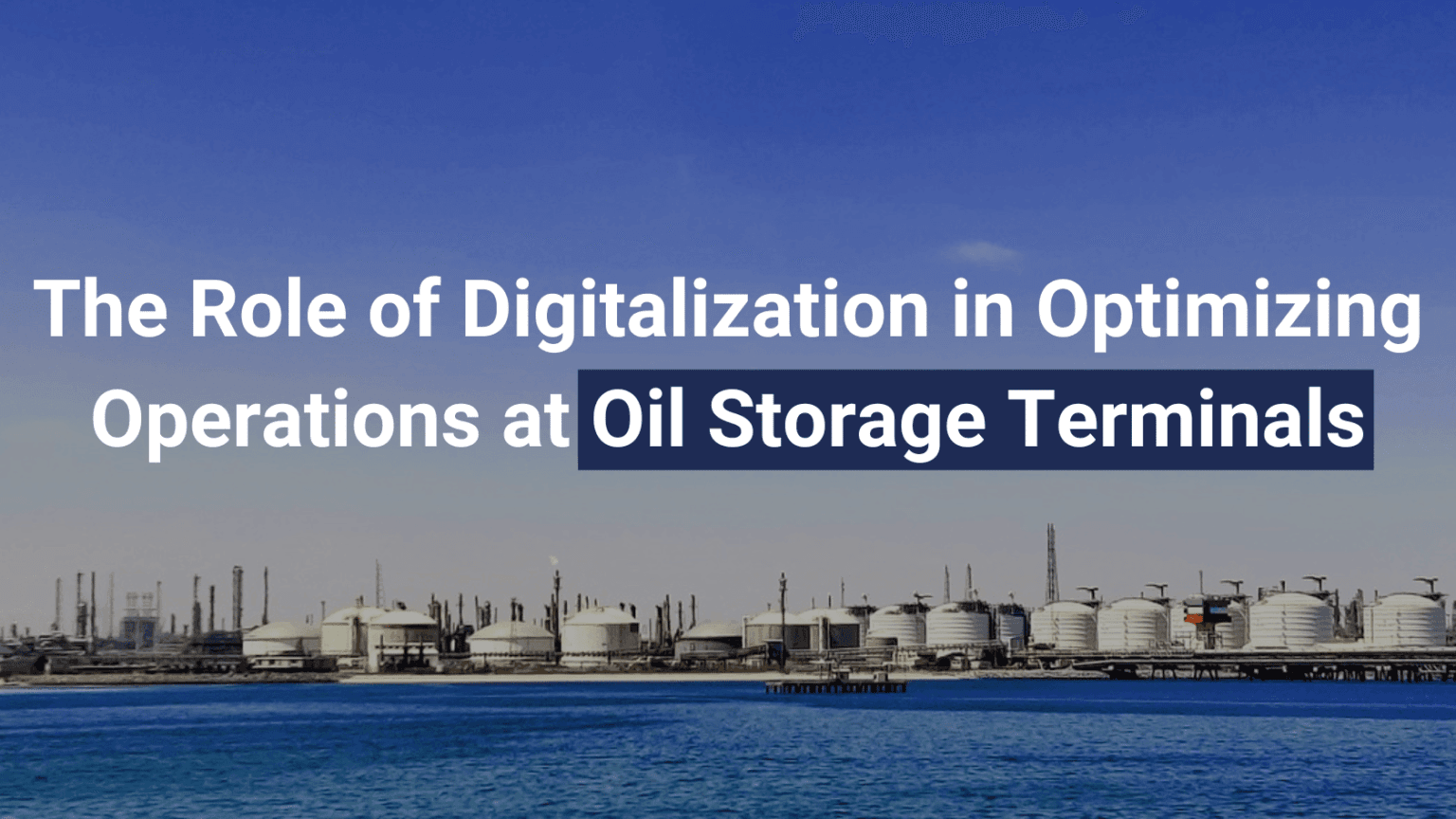

In an era of rapid technological advancement, the oil and gas industry is embracing digitalization to enhance efficiency, safety, and sustainability across all facets of operations. Oil storage terminals, vital components of the petroleum supply chain, are no exception. This article explores the transformative impact of digitalization on optimizing operations at oil storage terminals, from inventory management and maintenance to safety protocols and environmental monitoring.

Real-time Inventory Management:

Digitalization enables oil storage terminals to implement advanced inventory management systems that provide real-time visibility into product levels, storage capacities, and movements. By leveraging sensors, IoT devices, and data analytics, terminals can monitor inventory levels accurately, optimize storage utilization, and streamline logistics for timely deliveries and replenishments.Predictive Maintenance:

Traditional maintenance practices at oil storage terminals often rely on scheduled inspections and reactive repairs, leading to downtime and costly disruptions. Digitalization offers predictive maintenance solutions that leverage machine learning algorithms and sensor data to anticipate equipment failures, identify potential issues proactively, and schedule maintenance activities optimally. This approach minimizes downtime, extends asset lifespan, and reduces maintenance costs.

Enhanced Safety and Security:

Safety is paramount in oil storage terminal operations, where the handling of hazardous materials poses significant risks to personnel, infrastructure, and the environment. Digitalization enhances safety and security by deploying advanced monitoring systems, video surveillance, and perimeter controls to detect potential hazards, unauthorized access, and security breaches in real-time. Additionally, digital tools enable terminals to conduct virtual safety training, emergency drills, and risk assessments to mitigate operational risks effectively.

Automation and Optimization:

Digitalization facilitates automation and optimization of critical processes at oil storage terminals, improving efficiency and productivity while reducing human error and operational bottlenecks. Automated systems for tank gauging, blending, and product transfer enable terminals to streamline workflows, minimize manual interventions, and achieve greater throughput with fewer resources. Furthermore, optimization algorithms and predictive analytics optimize terminal operations, such as scheduling tanker movements, optimizing product mixtures, and reducing energy consumption for cost savings and environmental sustainability.

Environmental Monitoring and Compliance:Oil storage terminals must comply with stringent environmental regulations and industry standards to mitigate pollution risks and minimize environmental impacts. Digitalization enables terminals to monitor emissions, effluents, and waste streams in real-time, facilitating proactive environmental management and regulatory compliance. Advanced analytical tools and modeling techniques help terminals assess environmental risks, implement pollution prevention measures, and demonstrate compliance with regulatory requirements.

Conclusion:

Digitalization is revolutionizing the operations of oil storage terminals, enabling them to achieve unprecedented levels of efficiency, safety, and sustainability. By embracing digital technologies such as IoT, data analytics, and automation, terminals can optimize inventory management, implement predictive maintenance practices, enhance safety protocols, streamline operations, and ensure regulatory compliance. As the oil and gas industry continues to evolve, digitalization will play an increasingly vital role in shaping the future of oil storage terminal operations, driving innovation, and delivering value to stakeholders across the supply chain.