Mike N Dad is offering 3 types of pre-engineered steel structures.

- Hot rolled pre-engineered steel structure.

- Cold Formed Sections in Pre-Engineered Steel Structures.

- LGS construction method.

Hot Rolled Pre-Engineered Steel Structure

Hot rolled pre-engineered steel structures involve the use of steel sections that are fabricated through a high-temperature rolling process. These sections, which include I-beams, H-columns, and other profiles, are created by heating steel billets or ingots to high temperatures and then passing them through rollers to achieve the desired shapes. The plastic deformation that occurs during the rolling process imparts structural strength and load-carrying capacity to these sections. Hot rolled sections are commonly used for primary load-bearing components in large industrial and commercial buildings due to their robustness and ability to handle heavy loads.

Cold Formed Sections in Pre-Engineered Steel Structures

Cold formed sections in pre-engineered steel structures are fabricated by shaping thin steel sheets or strips at room temperature using bending, folding, and roll-forming techniques. These sections typically have a uniform cross-section and are created by forming the steel without the use of heat. Cold formed sections, such as purlins, girts, and wall studs, are used for secondary elements in buildings. While they may have slightly lower load-carrying capacity compared to hot rolled sections, cold formed sections are known for their versatility, cost-effectiveness, and ease of installation. They are often used to create lightweight, non-load-bearing components that contribute to the overall structural integrity of the building.

Light Gauge Steel (LGS) Construction Method

The Light Gauge Steel (LGS) construction method involves the use of galvanized steel C sections or profiles of varying thicknesses to create the structural framework of a building. LGS sections are cold-formed from galvanized steel coils and are manufactured using computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. LGS construction offers precision, durability, sustainability, and speed of construction. LGS systems are known for their structural strength, recyclability, and resistance to environmental factors like rust, rot, mould, and insect damage. LGS is versatile and suitable for various building types, and it is especially known for its rapid construction process due to the lightweight and pre-fabricated nature of its components.

Summary:

The three types of pre-engineered steel structures,

- Hot rolled

- Cold formed sections

- LGS construction,

differ in their manufacturing processes, material properties, load-bearing capacity, and applications. Hot rolled sections are heat-formed for primary load-bearing elements, cold formed sections are shaped at room temperature for secondary components, and LGS construction utilizes cold-formed galvanized steel sections for a versatile, sustainable, and efficient construction method.

Pre-Engineered Steel Structure

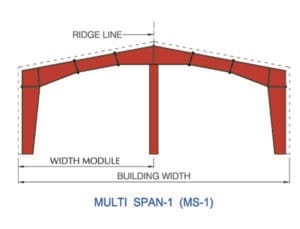

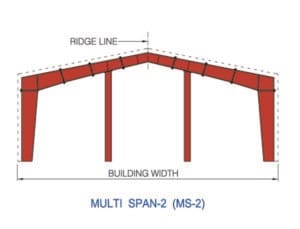

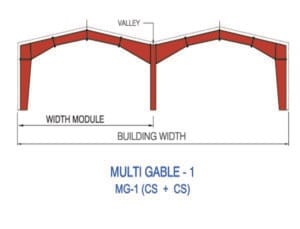

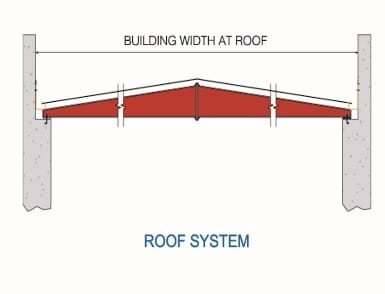

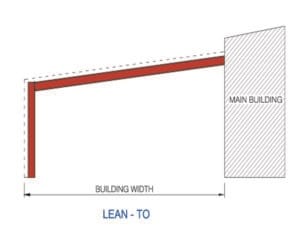

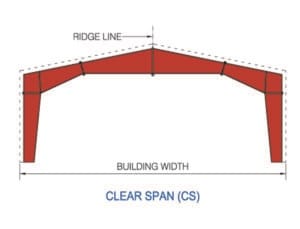

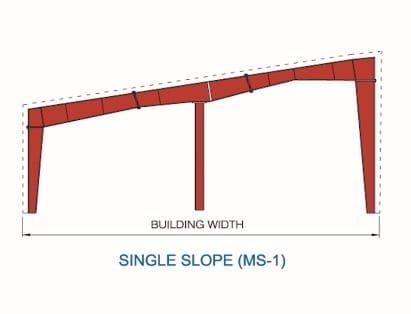

The Primary Framing System

The Secondary Framing System

Mezzanine Systems

Enhancing Architectural Versatility within the realm of architecture, the concept of a mezzanine assumes a pivotal role as an intermediary floor that gracefully bridges the expanse between main levels within a building. This unique architectural feature possesses an inherent elegance, often projecting itself from the walls to create an inviting spatial dimension that maintains an interconnected visual continuity between the ceiling above and the floor directly below. This design hallmark, succinctly put, leads to a harmonious convergence of the mezzanine floor and the floor beneath, sharing a singular ceiling.

Enhancing Architectural Versatility within the realm of architecture, the concept of a mezzanine assumes a pivotal role as an intermediary floor that gracefully bridges the expanse between main levels within a building. This unique architectural feature possesses an inherent elegance, often projecting itself from the walls to create an inviting spatial dimension that maintains an interconnected visual continuity between the ceiling above and the floor directly below. This design hallmark, succinctly put, leads to a harmonious convergence of the mezzanine floor and the floor beneath, sharing a singular ceiling.

In industrial contexts, the application of mezzanine floor systems unveils its pragmatic utility. Positioned as semi-permanent structures, these systems find their purpose within existing buildings, effectively carving a new operational realm between two permanent stories. Notably, the inherent versatility of these structures is underscored by their freestanding nature, offering an inherent advantage of modularity – a feature that seamlessly facilitates disassembly and relocation, as dictated by the operational exigencies.

Here at Mike N Dad, our domain of expertise extends fervently to the realm of Mezzanine Systems. This specialized facet finds its pinnacle of application within industrial landscapes, notably in sectors such as warehousing, distribution, and manufacturing. If the pursuit of optimal material handling efficiency and manufacturing flexibility lies at the core of your operational ethos, Mike N Dad stands poised to transform your space. Our meticulously designed mezzanine systems are imbued with the precision to seamlessly harmonize with your load and material flow requirements, ushering in an era of streamlined productivity.

In the tapestry of architectural innovation, mezzanine systems represent a dynamic interplay of form and function. A fusion of elegance and utility, these systems redefine spatial possibilities, mirroring our commitment to catalyzing efficiency through thoughtful design.

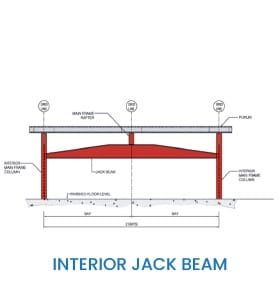

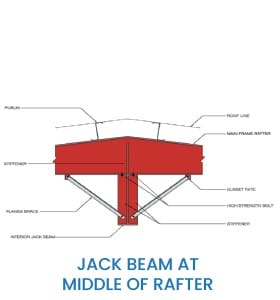

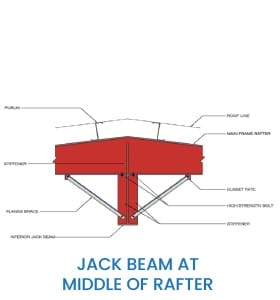

JACK BEAMS

ELEVATING POSSIBILITIES

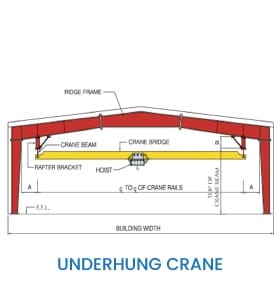

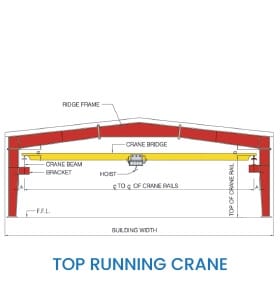

Our Crane System Expertise in the realm of crane systems, RME steel emerges as your trusted partner, providing a specialized range of components that lay the foundation for seamless operations. Our expertise revolves around the supply of critical elements, including column/rafter brackets and the fundamental crane runway beams – essential pillars that uphold the crane system’s functionality.

However, our commitment doesn’t stop at the supply stage. At RME, we believe in a holistic approach. We delve deep into understanding your unique requirements, enabling us to craft a bespoke solution tailored to your needs. Our skilled team takes charge of designing and estimating the crane system, ensuring it aligns perfectly with your project’s specifications.

Unveil a world of possibilities as we introduce you to the myriad of crane systems that harmonize effortlessly with pre-engineered steel buildings. Our repertoire includes the esteemed Top Running Cranes, a hallmark of precision and efficiency. For those seeking innovation beneath the surface, our Underhung Cranes redefine possibilities, maximizing space utilization.

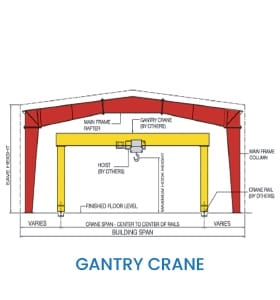

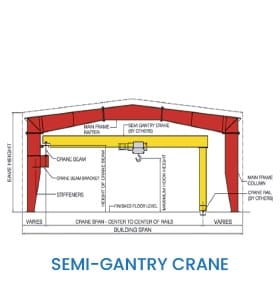

Monorail Cranes take center stage, offering a streamlined solution for targeted movements, while Jib Cranes pivot gracefully, augmenting maneuverability within confined spaces. Gantry Cranes, a symbol of robust strength, stand ready to meet the demands of heavy-duty lifting, while Semi Gantry Cranes bridge the gap between versatility and cost-effectiveness.

Experience the symphony of engineering excellence as RME steel elevates your project through a comprehensive array of crane systems. From inception to implementation, we stand by your side, ensuring every aspect of your crane system journey is characterized by innovation, precision, and unrivalled dedication. Welcome to a new era of elevated possibilities. Welcome to RME steel.

Erection Services

- Material and Properties: LGS construction employs galvanized steel C sections, which are cold-formed from galvanized steel coils. The galvanization process involves coating the steel with a layer of zinc to enhance its corrosion resistance and durability. This makes LGS highly resistant to rust, rot, mould, mildew, and insect damage, ensuring the long-term integrity of the building.

- Precision and Consistency: LGS components are manufactured using computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. This results in precise dimensions and consistent quality for each steel section, ensuring a high level of accuracy during construction.

- Recyclability and Sustainability: LGS construction is environmentally friendly and sustainable. The steel used in LGS systems is recyclable, with a significant portion of its material content coming from recycled sources. This reduces the environmental impact and supports sustainable construction practices.

- Structural Strength: Despite its lightweight nature, LGS is remarkably strong and can support significant loads. The precise manufacturing process and high-quality steel contribute to the structural integrity of LGS buildings. LGS systems are designed to meet stringent building codes and standards.

- Versatility: LGS construction is versatile and suitable for various types of buildings, including residential, commercial, industrial, and institutional structures. The flexibility of LGS allows for creative architectural designs and adaptable floor plans.

- Speed of Construction: LGS construction is known for its rapid construction process. The pre-fabricated steel sections are lightweight and easy to handle, leading to faster assembly on the construction site. This can significantly reduce construction timelines compared to traditional methods.

- Energy Efficiency: LGS construction can incorporate effective insulation materials, resulting in energy-efficient buildings. The precise fit of components also helps minimize air leakage, enhancing overall thermal performance.

- Design and Integration: LGS construction integrates well with other building materials, such as concrete, glass, and wood. It can be combined with various architectural styles and finishes to achieve the desired aesthetic appearance.